|

|

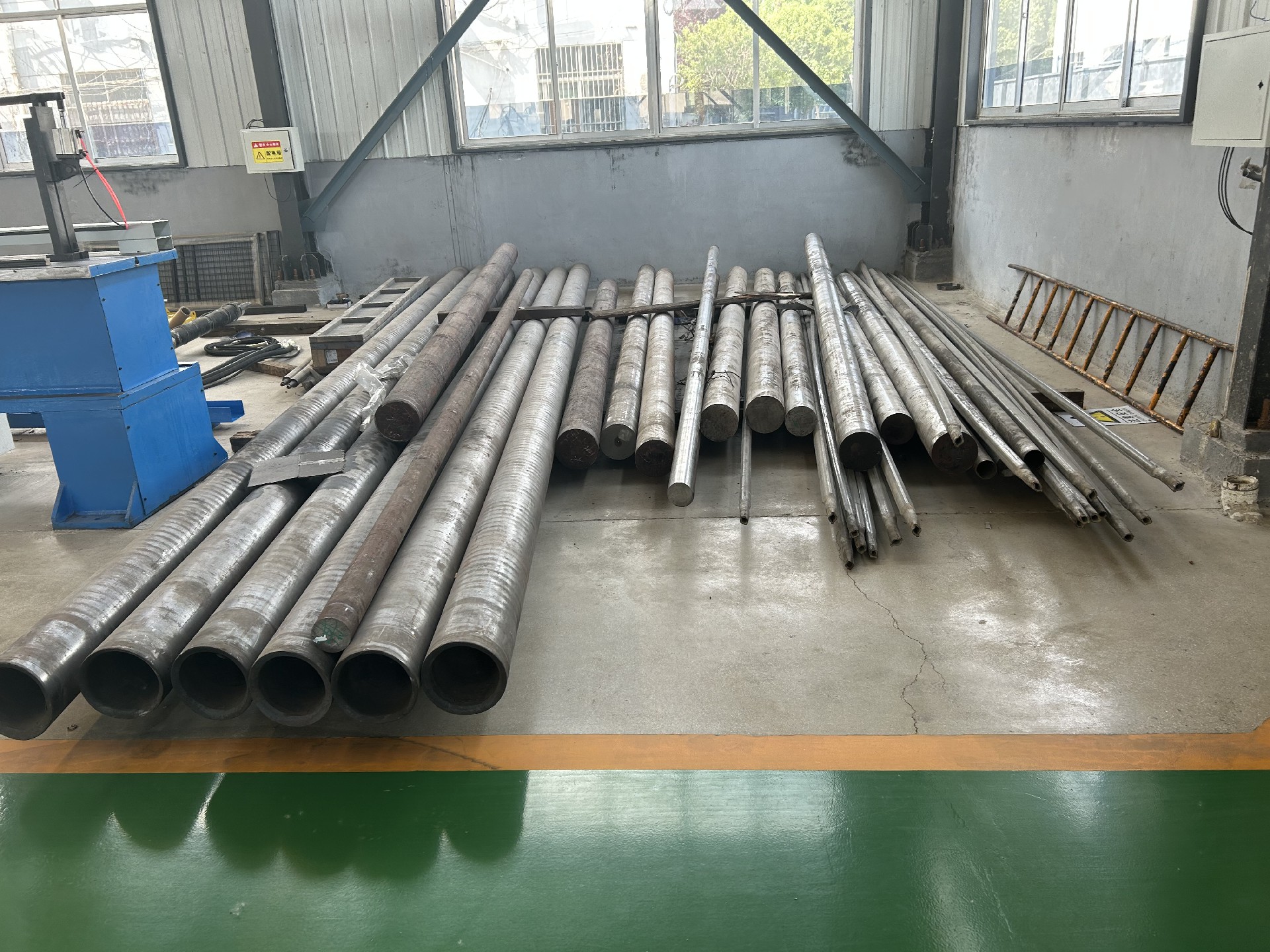

Automatic Tube Straightening Machine

|

APPLICABLE PRODUCT

PRODUCT DETAILS

1. Unmatched Speed & Efficiency

15-second cycle time per part with seamless integration of robotic loading, AI-powered vision inspection, and multi-axis servo systems.

3,000+ parts/day capacity per line, ideal for high-volume sectors like automotive drivetrains and robotics.

2. Sub-Micron Precision Guaranteed

Laser Matrix Measurement Technology (8-point real-time scanning) achieves ±0.005mm repeatability, surpassing ASME and ISO 2768 standards.

Adaptive AI algorithms auto-adjust force vectors for shafts, tubes, and asymmetric parts.

3. Cost-Smart Automation

Slash labor costs by 80%: Replace 8 operators per line with lights-out production.

Energy savings up to 40% vs. hydraulic systems, with predictive maintenance cutting downtime by 30%.

Near-zero material waste: AI optimizes correction paths, reducing scrap to <0.02%.

SITE:

SITE: